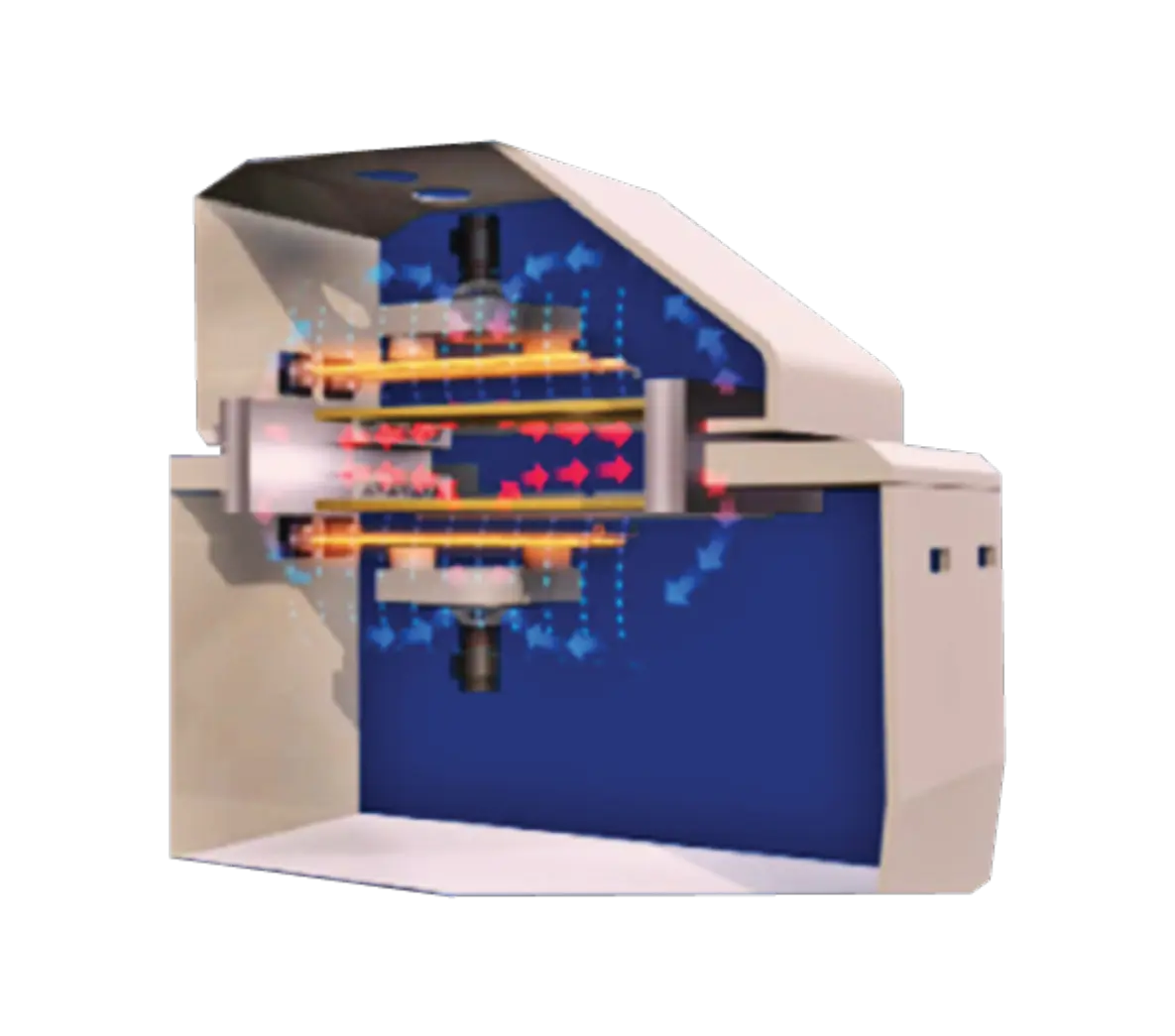

Der AR Serie Reflow Ofen kombiniert innovative Technologie mit Stickstoffintegration, um die Anforderungen moderner

SMT-Produktionslinien optimal zu erfüllen. Mit bis zu 12 Heiz- und 3 Kühlzonen bietet der SMD Ofen eine präzise und gleichmäßige Wärmeverteilung, die eine zuverlässige Verarbeitung von Leiterplatten sicherstellt.

Der SMD Lötofen minimiert durch Stickstoffoption Oxidationen im Lötprozess, was die Qualität und Langlebigkeit der Lötverbindungen erhöht. Das fortschrittliche Automatisierungssystem ermöglicht eine vollständige Prozesskontrolle mit automatischer Breitenverstellung, Rezeptverwaltung und Echtzeitüberwachung. Der AR Serie ist die ideale Lösung für Industrie 4.0 und verbindet Benutzerfreundlichkeit mit modernster Technik.

Warum Reflow-Löten der verlässlichste Lötprozess ist

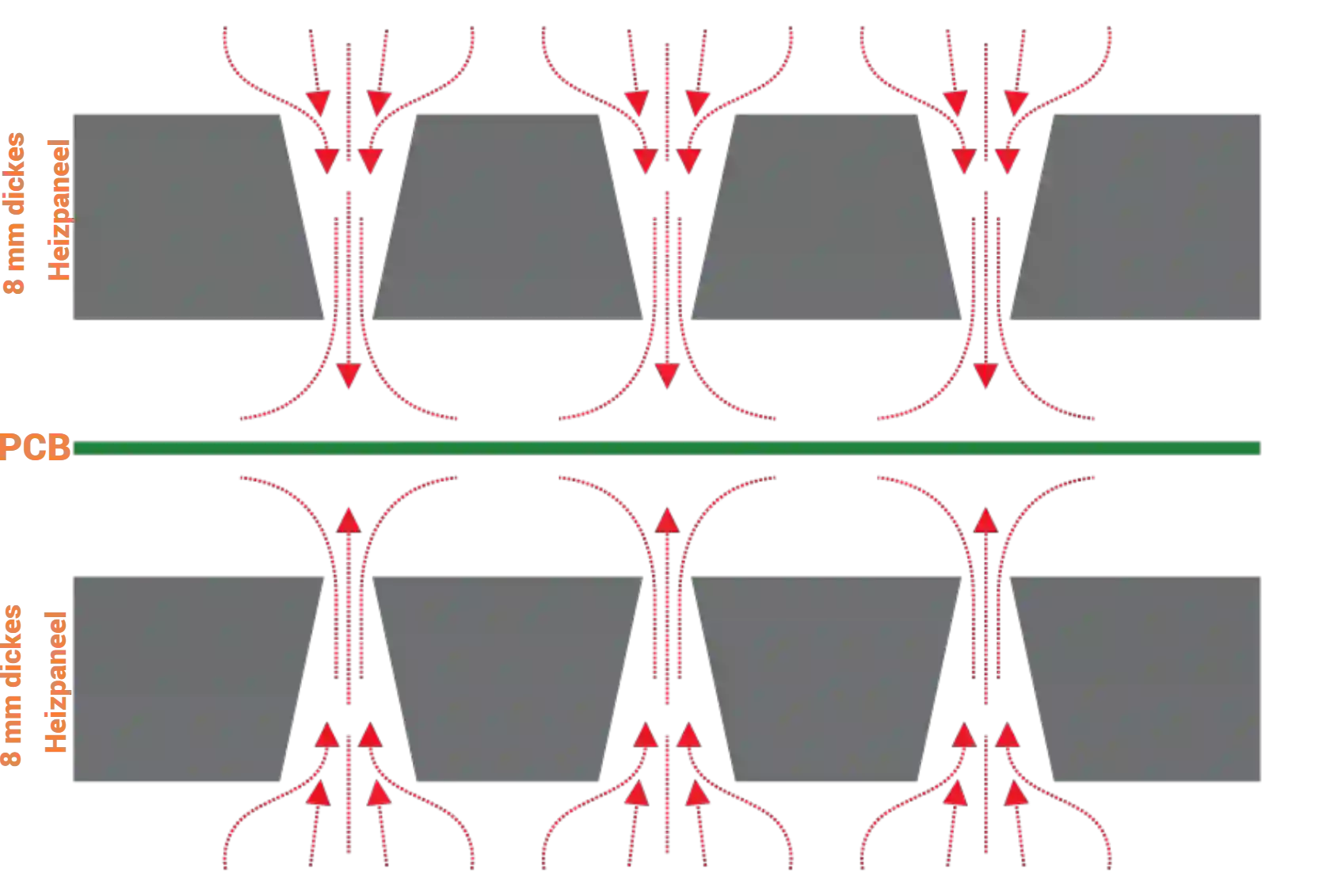

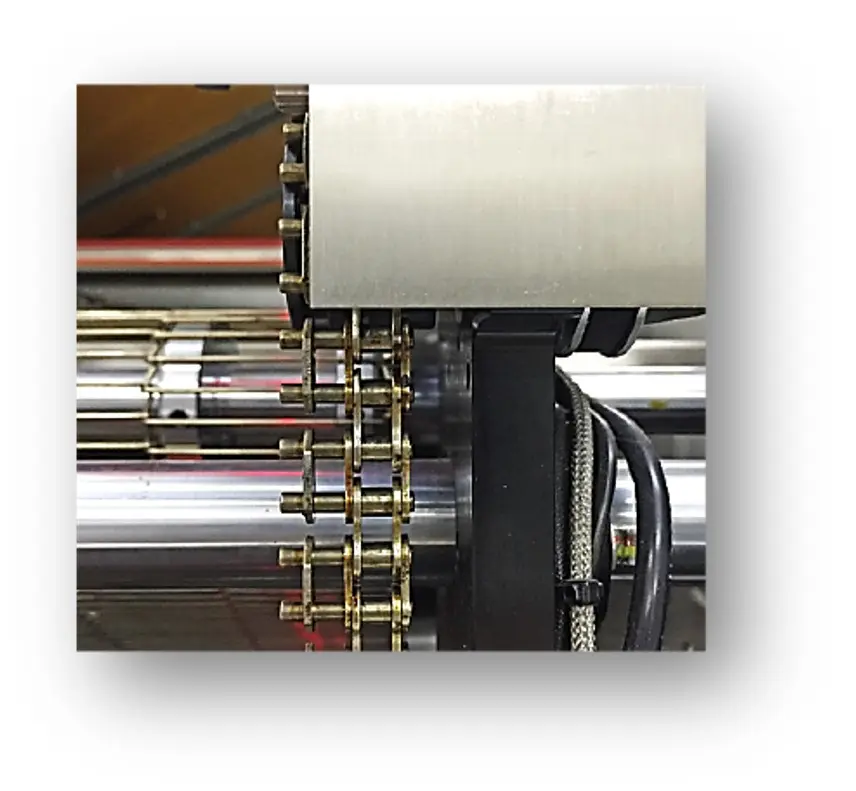

Heizsystem der AR Serie

Der AR Serie Reflow Ofen ist mit einem hochmodernen Heizsystem ausgestattet, das eine präzise und effiziente Wärmeübertragung gewährleistet:

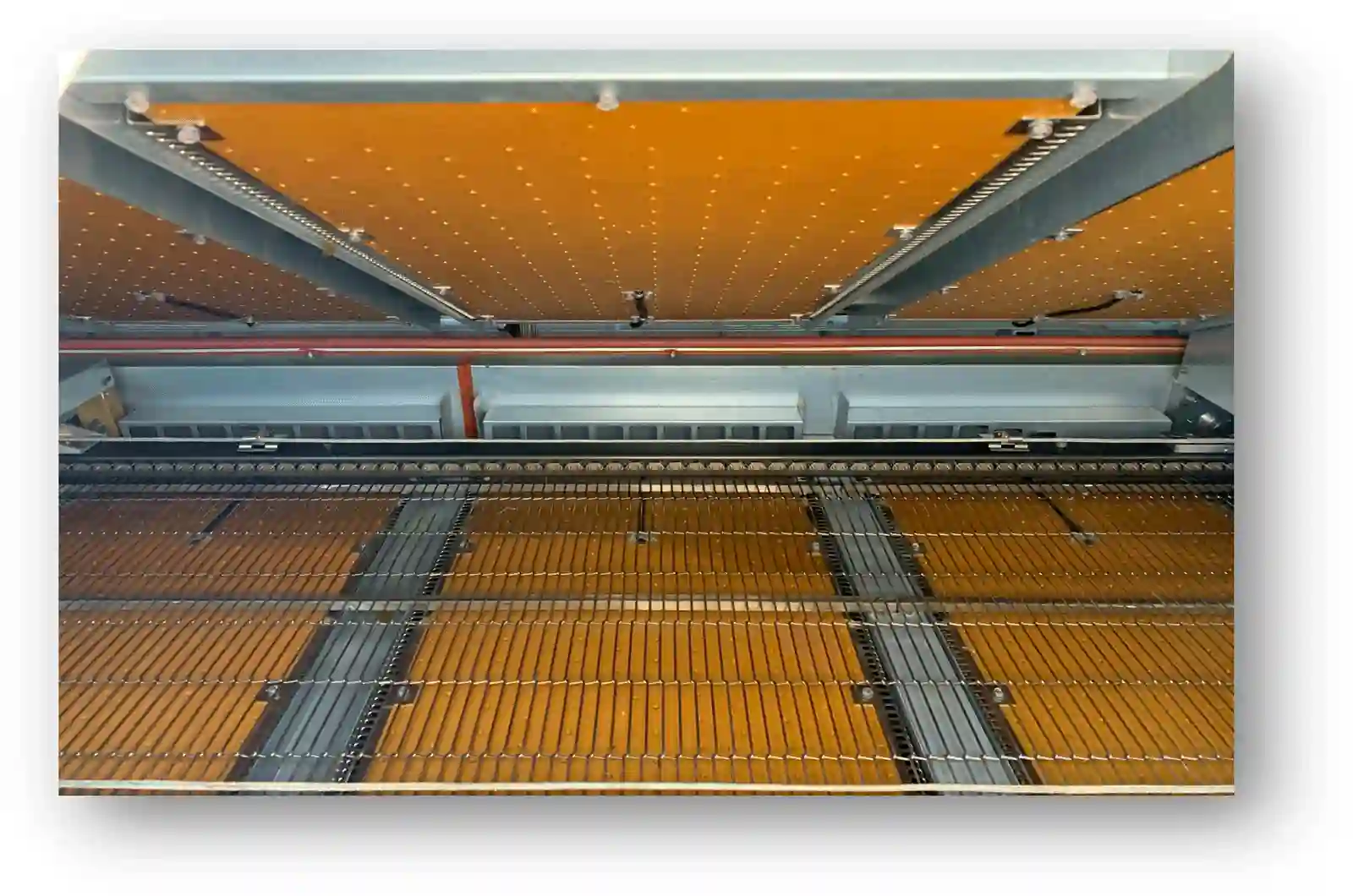

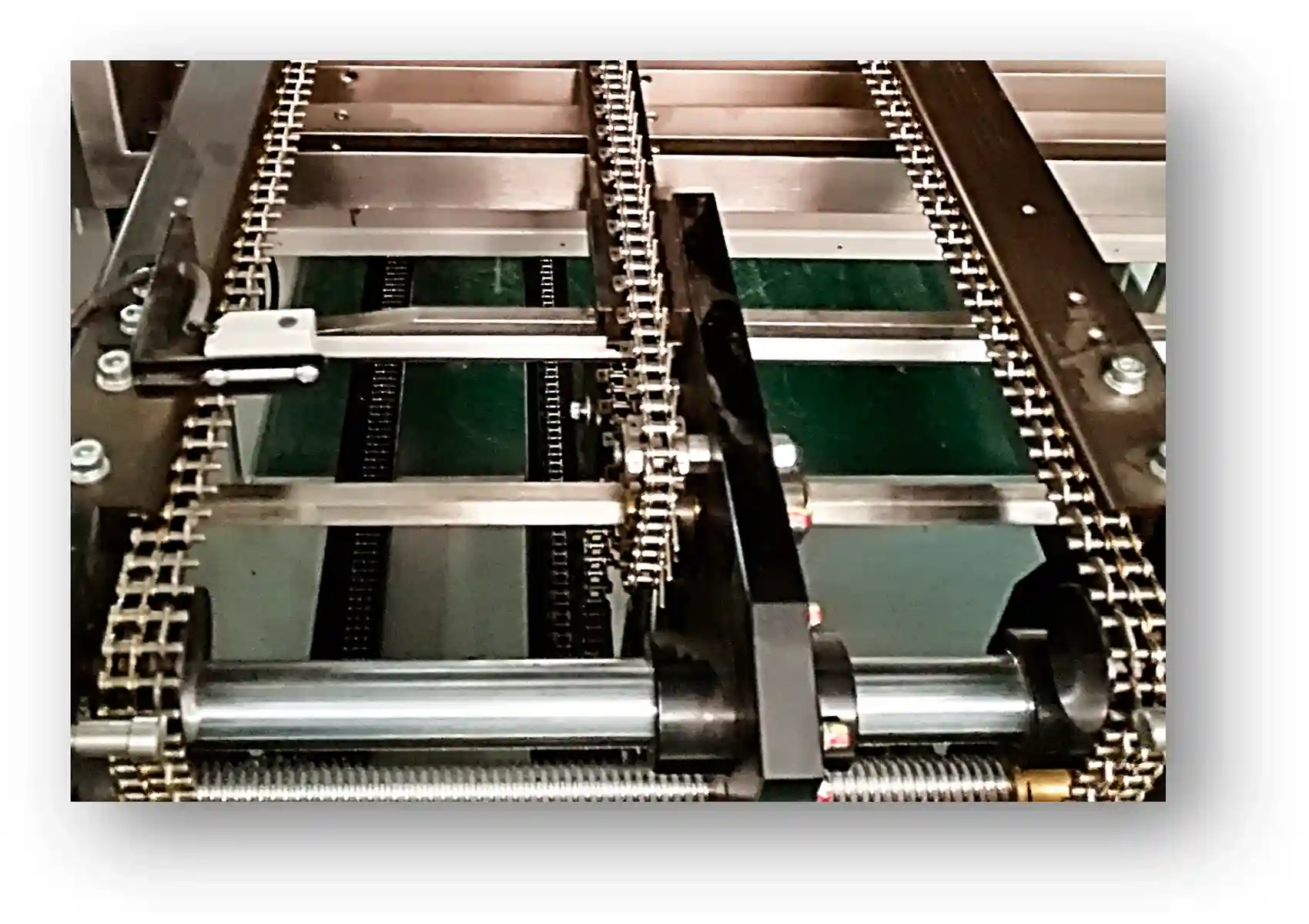

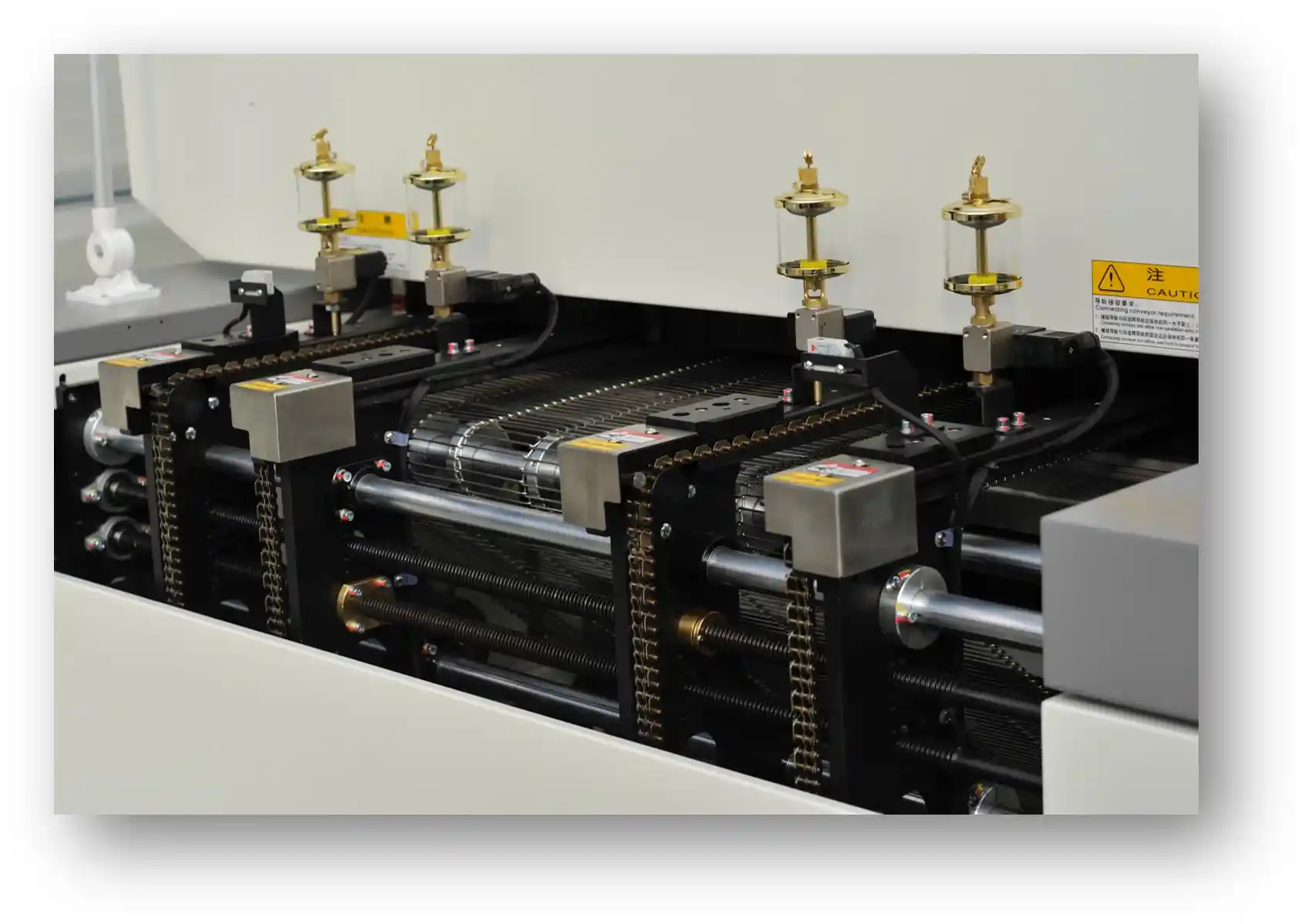

Fördersystem der AR Serie

Das Fördersystem des AR Serie Reflow Ofens ist zuverlässig und flexibel, um verschiedene PCB-Größen und Produktionsanforderungen zu erfüllen:

Vorteile von dem SMD Ofen

Reflow Ofen mit Stickstoff: Warum er entscheidend ist

AR Serie Reflow Öfen sind sowohl in Standardausführung als auch mit Stickstoffoption erhältlich, um die Anforderungen unterschiedlicher SMT-Produktionsprozesse zu erfüllen. Der AR Serie Reflow Ofen mit Stickstoff ist speziell dafür konzipiert, Stickstoff in den Lötprozess einzuführen, um die Qualität und Zuverlässigkeit der Lötverbindungen zu verbessern. Stickstoff verdrängt Sauerstoff und reduziert Oxidationen, die während des Lötens auftreten können. Diese Konfiguration ist besonders in der SMT-Produktion wichtig, um höchste Qualität zu gewährleisten, vor allem bei empfindlichen oder hochwertigen elektronischen Bauteilen.

Mehr über die Vorteile von Stickstoff erfahren Sie auf unserer N2-Generator-Seite. Wir bieten kostenlose Beratung, um Stickstoff effizient in Ihren Lötprozess zu integrieren.

Ihre SMT-Fertigung im Fokus: Unsere Komplettlösungen

Ihre SMT-Produktion verdient die beste Kombination aus Effizienz, Präzision und Qualität. Unsere Komplettlösungen bieten Ihnen

schlüsselfertige SMD Linien, die perfekt aufeinander abgestimmte Maschinen und modernste Technologien nutzen, um maximale Leistung zu gewährleisten.

Erfahren Sie, wie unsere schlüsselfertige SMD Linie Ihre SMT-Fertigung effizienter macht, und lassen Sie sich von unserem Team individuell beraten, um die perfekte Lösung für Ihre Produktion zu finden.

Wussten Sie schon? Wir haben auch einen WebShop in dem Sie weiterführende Informationen,

alle technische Details und noch mehr Maschinen für Ihre Produktion finden. Beraten lassen oder sicher und schnell bestellen.

Falls Sie noch keinen Zugang haben, können Sie dies hier ebenfalls kostenlos erledigen: