Der G-Tera Schablonendrucker setzt neue Maßstäbe in der SMT-Drucktechnologie, indem er Druckgeschwindigkeit, Präzision auf höchstem Niveau und ein flexibles Fördersystem vereint. Mit einer Kernzykluszeit von nur 5,2 Sekunden ermöglicht der G-Tera Schablonendrucker eine erhebliche Beschleunigung der Produktionsprozesse und reduziert die Gesamtzykluszeit um bis zu 40 %. Dank einer Druckgenauigkeit von ± 12,5 µm @ 6 Sigma, ≥2 Cmk gewährleistet der G-Tera Schablonendrucker eine außergewöhnliche Druckqualität und Präzision.

Ein besonderes Highlight von dem G-Tera Schablonendrucker ist das Auto Paste Replenishment System, das zwei 500g-Dosen Lotpaste automatisch auffüllt, sobald der Rollendurchmesser unter 10 mm sinkt. Dadurch wird ein ununterbrochener Betrieb von über 8 Stunden ohne manuellen Eingriff ermöglicht. Zudem bietet das Fördersystem des G-Tera Schablonendrucker die Möglichkeit, zwischen Single-Stage- und 3-Stage-Mode zu wechseln, wodurch es sich flexibel an Leiterplattengrößen von bis zu 510 x 510 mm anpassen lässt.

Superschnell

Kernzykluszeit: 5,2 Sekunden | Gesamte Zykluszeit: 12,5 Sekunden

Die verbesserte, linear-motorgetriebene “LIGHT-Bolt”-Passmarkenkamera (3,0 Megapixel, Sichtfeld (FOV): 8 x 10 mm) erfasst Passmarken auf Schablonen und Leiterplatten gleichzeitig und mit höchster Geschwindigkeit.

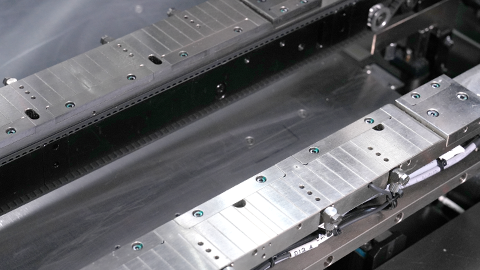

Das Fördersystem von dem G-Tera Schablonendrucker unterstützt sowohl den Single-Stage- als auch den 3-Stage-Mode, die automatisch über die Programmierung generiert werden. Im 3-Stage-Mode kann das Fördersystem Leiterplatten vorab laden, um die Lade- und Entladezeiten deutlich zu reduzieren.

Das verbesserte, linear-motorgetriebene Reinigungssystem arbeitet unabhängig und benötigt keine externe Energieversorgung. Dadurch werden Verzögerungen bei den Reinigungsvorgängen erheblich reduziert und die Effizienz des Druckprozesses maximiert.

Präzision auf höchstem Niveau

Nass-Druck-Fähigkeit: ± 12,5 µm @ 6 Sigma, ≥2 Cmk

Das Feedback-System für den Rakeldruck und die doppelt zylindergetriebenen Rakel überwachen den Druck in Echtzeit, verhindern Ungleichmäßigkeiten auf großen PCBs und sichern eine präzise Druckkraft von ±0,2 kg.

Das Stencil-Lock-System fixiert die Schablone mit einem Vakuum-Mechanismus beidseitig an der Fördererschiene. So bleibt der Kontakt zur Leiterplatte stabil, und das „Wellenwerfen“ der Schablone wird zuverlässig verhindert.

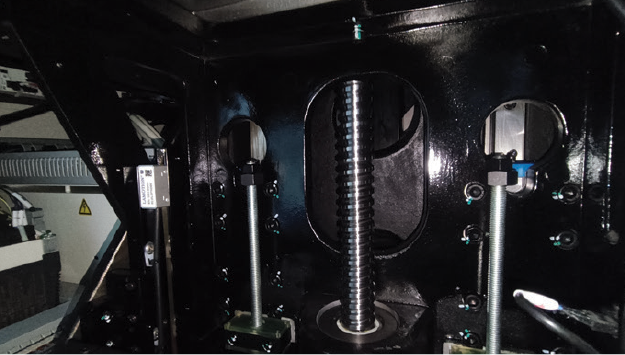

Das Echtzeit-Überwachungssystem für die Höhe des Drucktisches (Z-Achse) gewährleistet eine Genauigkeit von bis zu 15 Mikrometern und sorgt damit für gleichbleibend präzise Druckergebnisse.

Vielseitige Fähigkeiten

Die Echtzeitüberwachung der Lotpasten-Rollendicke sorgt für eine optimale Paste-Menge und konstante Rollgeschwindigkeit, wodurch eine gleichmäßige Verteilung und höchste Druckqualität sichergestellt werden.

Konsistenter Rand-zu-Rand-Druck: Versteckte, fixierte obere Folienklemmen lassen sich manuell herausziehen und mit der motorisierten Randklemme kombinieren, um dünne Leiterplatten präzise zu fixieren und optimal zu drucken.

Nachhaltige, papierlose Reinigung: Das neue selbstreinigende Schablonenreinigungssystem nutzt Vakuumsaugung und Schaber, verbessert die Reinigung erheblich und senkt den Verbrauch von IPA sowie fusselfreiem Papier drastisch.

Zukunftssichere Lösung

Vielseitige Dosierkompatibilität: Der G-Tera Schablonendrucker unterstützt sowohl Kleber- als auch Lotpastendosierung. Zwei Jetting-Ventiltypen ermöglichen eine präzise und flexible Dosierung direkt nach dem Druckprozess.

AGV-gestützter Schablonenwechsel: Der MES-Server steuert den Wechsel. Ein AGV bringt die neue und entfernt die alte Schablone. Mit der automatischen Lotpasten-Sammelfunktion wird ein autonomer Betrieb sichergestellt.

Automatische Lotpasten-Sammlung: Eine Papierrolle entfernt überschüssige Lotpaste und überträgt sie auf die neue Schablone, vollständig integriert in den AGV-gestützten Schablonenwechsel für höchste Effizienz.

Gesichtserkennung für Maschinenzugang: Steuert den Zugriff und passt die Displayhöhe automatisch an, um ergonomischen Komfort und sichere Bedienung zu gewährleisten.

Automatische Schabloneninspektion: Das System prüft programmierbar nach einer bestimmten Anzahl von Druckzyklen die Schablonenöffnungen und aktiviert bei Verstopfung automatisch einen Reinigungszyklus.

Automatisches Nachfüllsystem für Lotpaste: Das System kann zwei 500-g-Dosen Lotpaste aufnehmen und diese automatisch nachfüllen. Dies gewährleistet einen unterbrechungsfreien Betrieb über mehrere Stunden hinweg.

Ihre SMT-Fertigung im Fokus: Unsere Komplettlösungen

Ihre SMT-Produktion verdient die beste Kombination aus Effizienz, Präzision und Qualität. Unsere Komplettlösungen bieten Ihnen

schlüsselfertige SMD Linien, die perfekt aufeinander abgestimmte Maschinen und modernste Technologien nutzen, um maximale Leistung zu gewährleisten.

Erfahren Sie, wie unsere schlüsselfertige SMD Linie Ihre SMT-Fertigung effizienter macht, und lassen Sie sich von unserem Team individuell beraten, um die perfekte Lösung für Ihre Produktion zu finden.

Wussten Sie schon? Wir haben auch einen WebShop in dem Sie weiterführende Informationen,

alle technische Details und noch mehr Maschinen für Ihre Produktion finden. Beraten lassen oder sicher und schnell bestellen.

Falls Sie noch keinen Zugang haben, können Sie dies hier ebenfalls kostenlos erledigen: