Complete Line Solution and Beyond

Explore our range of in-line and standalone machines for every task in your production. We offer expert guidance to help you choose the right solution for your project.

Global Network and Logistics

We cooperate on long-term with proven global suppliers and pre-select the best price-to-performance ratio

Leasing & Renting Solutions

Cooperating with qualifyed partners in our industry, we will find short-term and machine-lifetime solutions for your project.

Installation Services

We provide turn-key solutions including installation, training and maintenance service.

Governmental Fundings

Money is literaly lying on the street, lets go for a walk and collect it. There are multiple topics supported by our governments, such as digitalisatioin and sustainability. Lets talk about that.

Buy Back Solutions

We love Oldtimers, let us find a solution to let yours live peacfuly its second life.

PCB Design & Prototyping

Our PCB design agency’s and own production lines are available to test and improve your design - if necessary.

Spare Parts & Consumables

We offer the right spare part for all manufacturers in our portfolio. Suitable consumables will also be available soon.

Smart electronics manufacturing with selected partners from the global top 3 rankings.

Smart electronics manufacturing with selected partners from the global top 3 rankings.

In the SMT sector, we offer turnkey solutions for your manufacturing challenges, based on our portfolio of top-class hardware and software products for overall optimization. We achieve the best price-performance ratio through flexible building blocks along the entire production line and a step-by-step approach tailored to your requirements. Already have a design, materials, or even a prototype? Let’s work together to find the perfect solution. With our own production lines, we can perform not only theoretical evaluations but also practical tests. By partnering with the strongest global players, you can grow without limits with us. We also offer a flexible upgrade path into automation, with cost-effective stencil printers, pick-and-place machines, and ovens from our eco-class. All our systems are Industry 4.0 ready, modular, and scalable.

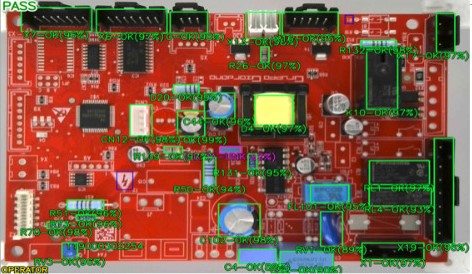

Trust is good, but control is better!

Trust is good, but control is better!

Monitor and archive every production step to continuously improve your processes and ensure the highest quality for your customers. Our machines provide interfaces to upstream and downstream operations in the production line, along with traceability options, laying the foundation for Industry 4.0.

- First Article Inspection

A simple offline inspection procedure for your pilot series (0-series). - 2D/3D Solder Paste Inspection (SPI)

Traceable inspection of your solder paste application. Alternatively, this step can be handled by our solder paste printer or AOI. - Pre-reflow 3D AOI (Automated Optical Inspection)

Positioned before the reflow oven, this unit monitors your pick-and-place process, allowing for optimization and traceability. It inspects polarity, misalignment, and missing components. - Post-reflow 3D AOI

Real-time results inspection, supported and archived by artificial intelligence. These flexible AOI machines deliver maximum precision with an adaptive ultra-high-resolution tube and high speed. The AI continuously adjusts brightness, component height, and contrast to achieve the best possible results. - Automated X-Ray Inspection (AXI)

At the end of the production process, AXI inspects complex components on your PCBs (BGA, BTC, press-fit connectors, modules, etc.). The built-in AI continuously learns and delivers faster and more accurate results with each scan. This rephrased version is clear and concise, emphasizing the features and benefits while maintaining the technical detail.

OMO – One Man Operation Concept

OMO – One Man Operation Concept

Various solutions for the selective coating process of your PCBs – from simple and cost-effective nano-coating to a full production line. Our efficient OMO solution, featuring a pallet return conveyor and optical inspection, provides a complete solution for production, process optimization, quality assurance, and environmental sustainability in conformal coating.

- C Series Conformal Coating Machines

- jCURE+ Series Curing Ovens

- Automated Inspection Machines

- Board Handling Machines

The machines are Industry 4.0 ready, with connectivity to your ERP systems and optional traceability throughout the entire process.

Oddform components and THT (Through-Hole Technology) remain widespread in the electronics industry.

Oddform components and THT (Through-Hole Technology) remain widespread in the electronics industry.

THT machines improve process stability, increase quality and speed, and minimize human errors. They even enable component placement that would be impossible to achieve manually. Both hybrid placement machines and specialized THT automation systems can streamline your production process. You won’t have to sacrifice any of your usual optimizations: traceability, optical inspections, and pre-production management are all integrated into our THT solutions and are a core part of our offering. How does THT automation work? If you already have a prototype or a finalized PCB design, let us conduct an in-house study to determine the potential level of automation. Next, we’ll offer you the appropriate placement machine along with a theoretical ROI. Following this, we’ll provide advice on the results and, if necessary, suggest adjustments to the design, component packaging, and automation level. This ensures the highest possible degree of automation, all while keeping your project’s realistic budget in mind. A hybrid solution in THT placement is the most common approach, meeting the high standards of Industry 4.0.

Automated Cleaning for Various Applications

Automated Cleaning for Various Applications

Save time and money with our versatile cleaning systems. Our machines are true multitaskers, handling various tasks such as cleaning PCBs, stencils, and other components—all with the same machine. Cleaning PCB assemblies after the soldering process significantly improves the reliability of electronic devices. Environmental Benefits with Cost Savings! Closed-loop systems not only benefit the environment but also reduce costs. Many of our machines are eligible for subsidies, making them an even smarter investment.

Our Cleaning Portfolio Includes: PCB cleaning, printer stencil cleaning, cleaning of mechanical parts and nozzle cleaning for pick-and-place machines. The machines handle the cleaning, rinsing, and drying processes fully automatically. Effective cleaning of stencils with fine pitch components like 01005 and 03015. Rinsing can be done in open, closed, or half-closed loop processes. Smartlink-SMT provides comprehensive process documentation, along with MES integration and production line automation solutions.

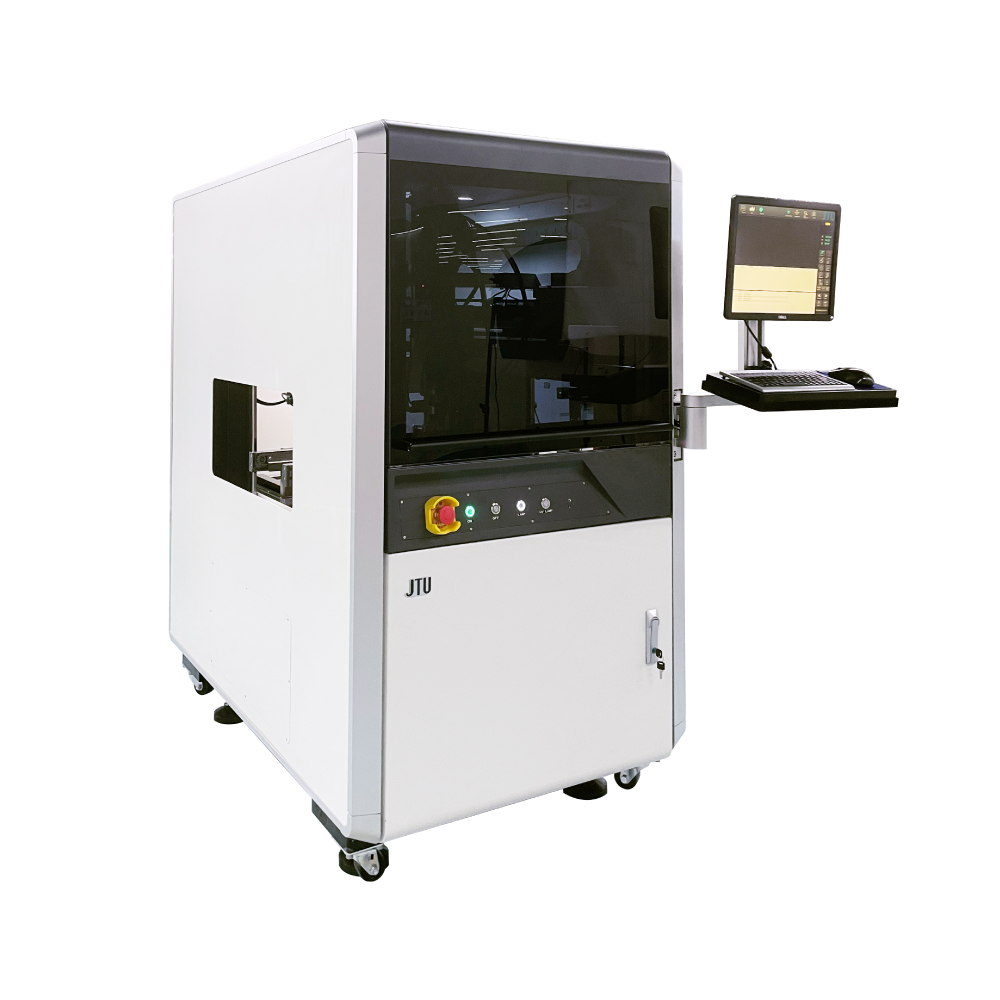

Solder paste Storage & Management

The comprehensive JTU solder paste management system offers a fully automated all-in-one solution for managing your solder paste. Now is the time to say goodbye to waste and difficult storage issues, thanks to the following features:

- Quality assurance

- Complete traceability

- Handling of opened cans

- Solder paste management

- All-in-one fully automatic system (refrigeration, thawing & stirring)

- Intelligent inventory management

- Full automation with controlled solder paste quality

- Optimal conditions for solder paste storage

- Complete traceability

- First-In-First-Out (FIFO) & First-Expired-First-Out (FEFO) automation

- Industry 4.0 ready

Discover our NPM series of modular nitrogen generators.

Discover our NPM series of modular nitrogen generators.

These extremely compact and quiet converters save you space and costs on the production line. With various sizes, we cover the complete range of SMT production. The format is always plug-and-play.

- NPM Series Modular Nitrogen Generators

- A range of models for different nitrogen applications

- Utilizes pressure swing adsorption (PSA) technology

- Modular design with a small footprint

- Excellent nitrogen quality

- Very low maintenance

- Applications: Selective soldering machines, conformal coating and dispensing machines, as well as N2 drying cabinets, etc.

PCB Handling, Depanelizing, Cutting & Workstations

PCB Handling, Depanelizing, Cutting & Workstations

Smartlink-SMT offers a range of solutions for your manufacturing line.

Handling: Complete automation in and around the production line. From simple conveyors to AGVs for your PCB magazines, we provide ready-made and modular solutions. PCB separators from Aurotek are available as cost-effective desktop units or fully automated inline solutions with robotic arms. The solutions also include transport AGVs to cover long distances between different production steps. Workstations Complex manual tasks within the line can be easily addressed with our ergonomic workstations. As part of the traceability platform, you will always know exactly which process step was completed and when. Handling is also fully integrated into Industry 4.0.

blank space

Visit Electronica with us! 12-15. Nov 2024

Discover electronica As the world’s leading trade fair, every two years electronica provides a comprehensive update of the rapidly developing technology in all fields of electronics. Here, leading companies present forward-looking innovations and use [...]

Brand New Panasonic Auto Setting Feeder

New Panasonic Auto Setting Feeder Brings Autonomous SMT Production One Step Closer The Panasonic Auto Setting Feeder is a breakthrough in automated parts supply with automatic loading improving work efficiencies by reducing labour and [...]

Meet us at the Panasonic Connect2Customers ‘Oct24

Connect2Customer Days 2024 Experience the Autonomous Factory Concept! Live demos, customer success stories, and insights to enhance your equipment efficiency: Leading industry partners share their expertise.

Navigation

© Copyright 2025 | SmartLink