GL-Star Printer – Precision, Flexibility, and Efficiency for SMT Production Lines

GL-Star Printer –

Precision, Flexibility and Efficiency

for SMT-Production Lines

Precision, Flexibility and Efficiency

for SMT-Production Lines

The GL-Star is a fully automatic stencil printer specifically designed to meet the demands of modern SMT production lines. With high-precision machine vision, innovative clamping mechanisms, and fully automated processes, the GL-Star ensures perfect printing results, reduces manual intervention, and boosts your production efficiency.

Combining precision, flexibility, and Industry 4.0 readiness, the GL-Star stencil printer is equipped with intelligent features such as automatic stencil alignment and optional upgrades. It is the ideal choice for manufacturers aiming to improve quality and efficiency in their SMT operations.

Why the GL-Star Printer is the Right Choice for You:

Standard Features

Auto Stencil Positioning

The stencil Y-position is adjustable via user interface, and the settings can be saved and reapplied when replacing the stencil. This function significantly reduces human errors and saves time in readjusting stencil position.

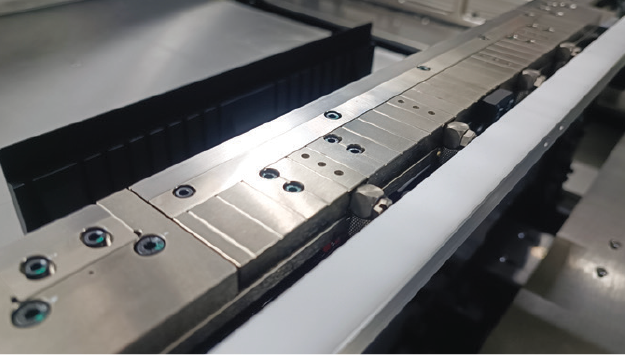

Stencil Lock

The stencil lock vacuum suction firmly holds the stencil on both sides of the conveyor during printing cycle, eliminating stencil vibration by having firm contact with the PCB.

Back to Back Ready

2 machines back-to-back are perfect match for dual-lane SMT line. Therefore, the internal structure of the GL-Star is pre-assembled in back-to-back configuration. It can be used as a stand-alone unit, or additional equipment can be seamlessly added in a back-to-back mode in future.

PCB Clamper

The PCB clamper is a combination of retractable top clamp and motor controlled side clamp, uniquely designed by GKG (patented). With these standard features, all of today’s available and challenging substrates can be securely clamped and print to the highest quality.

Optional Features

Ready for Industry 4.0

Through machine status, parameters can be uploaded automatically. Designed to support customers’ advancement towards Industry 4.0 intelligence production, GL-Star provides seamless connection with users’ MES system, enhancing product traceability and maintenance needs.

SPI Closed-loop Connection

The system automatically adjusts the solder paste deposition based on SPI feedback regarding print quality. Compatible with software from TRI, Koh Young, Pemtron, Parmi, Saki and many others.

Paste Rolling Diameter Monitoring System

Tracing solder paste rolling diameter in real time and trigger the auto dispensing if it falls below 10 mm. Completely eliminate insufficient solder paste on stencil and keep the paste rolling speed within optimum range to achieve best printing result with this smt printer.

Auto Paste Dispensing

The paste is automatically dispensed across the entire squeegee length, maintaining at 15 mm rolling diameter, adopting the common 500 grams’ solder paste jar. Completely eliminates the wastage of solder paste overflowing to the sides of squeegee.

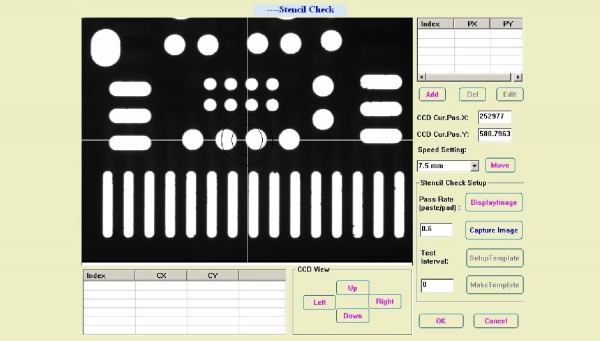

Stencil Aperture Inspection System

Using panel light installed at the top and CCD camera below to inspect stencil apertures. It automatically detects the clogging of stencil apertures to eliminate poor quality stencil being used, ensure quality printing right from the start.

Temperature & Humidity Display System

The temperature and humidity display system provides real-time monitoring of the internal temperature and humidity status of the equipment. This system is beneficial for monitoring and extending the lifespan of solder paste to ensures printing quality.

Your SMT Production in Focus: Our Turnkey Solutions

Your SMT production deserves the optimal combination of efficiency, precision, and quality. Our turnkey SMT lines provide fully integrated solutions with perfectly synchronized machines and cutting-edge technologies to ensure maximum performance and process reliability.

Discover more about our complete SMT line solutions and get expert advice from our team to find the perfect setup for your production needs.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here:

Navigation

© Copyright 2024 | SmartLink